Aseptic Processing Equipment

For injectable, vaccine, and ampoule lines with complete automation and sterility.

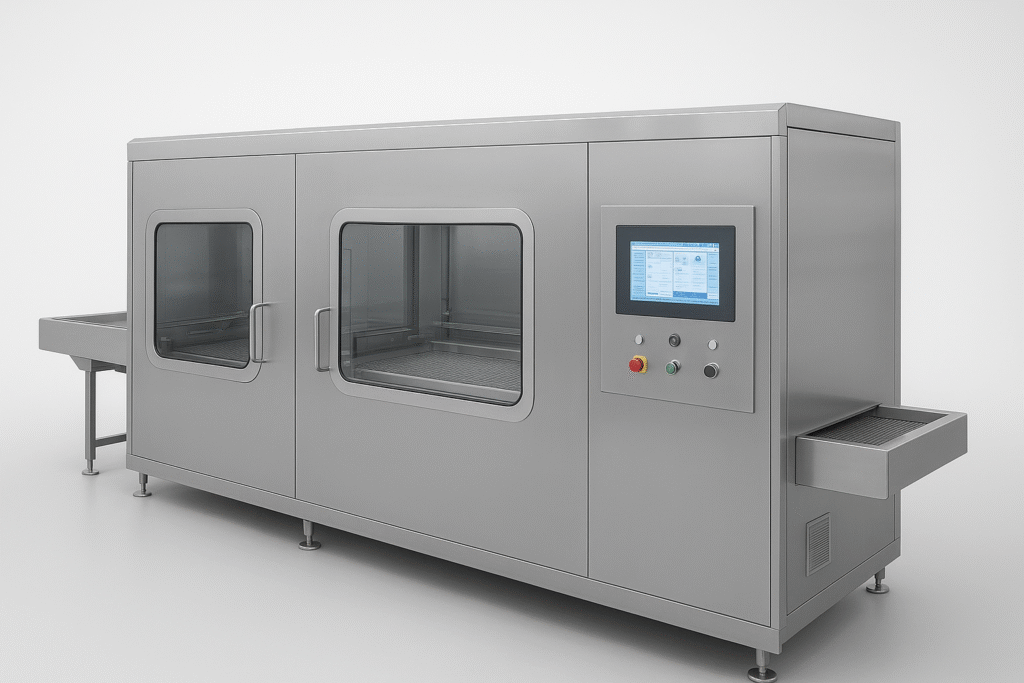

Our high-performance vial/ampoule washer ensures particulate-free containers prior to sterilization. With precision wash cycles, multiple water-air rinses, and minimal glass-to-glass contact, it safeguards container integrity while meeting GMP standards.

Key Features & Benefits :

✅Multi-Stage Washing – WFI and compressed air rinse.

✅ No Glass-to-Glass Contact – Reduces breakage risk.

✅ Automated Cycle Control – Consistent quality.

✅ 316L Stainless Steel – Hygienic, corrosion-resistant.

✅ Validation Ready – 21 CFR Part 11 compliant.

Applications :

Ideal for sterile injectable preparation lines

Key Features & Benefits :

✅ Continuous HEPA Airflow – ISO Class 5.

✅Validated Temperature Profile – Reliable endotoxin removal.

✅ Energy-Efficient Heating – Lower operational costs.

✅Full Automation – Seamless integration with washer and filler.

✅ Robust Build – 316L stainless steel.

Applications :

Sterile production lines for injectables, vaccines.

The modular filling, bunging, and sloppering station delivers precise dosing with minimal product loss, integrated with sterile component placement.

Key Features & Benefits :

✅High Fill Accuracy – Servo-driven systems.

✅ In-Line Stoppering – Controlled under laminar flow.

✅ Minimal Product Waste – Optimized design.

✅ Flexible Format Changes – Quick adjustments.

✅ CIP/SIP Ready – Easy cleaning and sterilization.

Applications :

Sterile liquids, vaccines, biotech formulations.

The capping unit secures aluminum caps onto vials with consistent torque, ensuring container closure integrity post-filling.

Key Features & Benefits :

✅ Consistent Torque Application – Reliable seal.

✅High Throughput – Matches upstream line speed.

✅ Compact Footprint – Space saving.

✅Minimal Maintenance – Rugged mechanics.

✅ GMP-Compliant Design – Smooth, cleanable surfaces.

Applications :

Sterile injectable packaging lines.

Key Features & Benefits :

✅High-Pressure Water Jets – Effective cleaning.

✅HEPA Drying – Particle-free finish.

✅ In-Line Operation – No process interruptions.

✅Water Recovery System – Sustainable operation.

✅Compact & Hygienic Build – Easy to clean.

Applications :

Pharma production for sterile injectables.

Key Features & Benefits :

✅ Servo-Controlled Label Placement – Accurate alignment.

✅Vision Inspection – Ensures correct label placement.

✅Quick Changeover – Minimal downtime.

✅Compact Footprint – Saves space.

✅ GMP-Grade Build – Easy cleaning.

Applications :

Sterile injectables, biotech products.

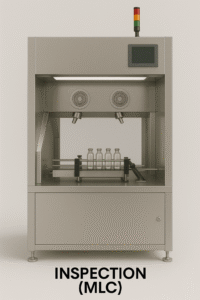

Key Features & Benefits :

✅Camera-Based Vision System – High detection accuracy.

✅360° Container Scanning – Complete coverage.

✅ Reject Mechanism – Automated removal of defective units.

✅Configurable Parameters – Matches product needs.

✅Data Logging – Supports quality assurance.

Applications :

Sterile production for parenteral drugs.