Bioclean Equipment

Designed to maintain ultra-sterile working conditions for sensitive operations

The Horizontal Laminar Airflow (HLAF) unit is engineered to deliver ISO Class 5 clean air by directing filtered airflow horizontally across the workspace. Designed for pharmaceuticals, biotechnology, and research environments, HLAF ensures product integrity through unidirectional airflow, effectively removing airborne contaminants.

Key Features & Benefits :

✅ Advanced HEPA Filtration – ISO Class 5 particle-free operations.

✅ Uniform Airflow Velocity – Maintains laminar flow consistency.

✅ Ergonomic Design – Spacious work area, low noise, glare-free lighting.

✅ High-Grade Stainless Steel – Corrosion-resistant and easy to clean.

✅ Energy-Efficient Motor – Lower operational costs without performance loss.

Applications :

Aseptic preparations, media transfers, sterile device assembly, quality control testing.

Why Choose Our HLAF?

Precision airflow balancing, GMP compliance, low-vibration comfort, and modular integration make HLAF the ideal choice for strict contamination control.

The Reverse Laminar Airflow (RLAF) system is built to protect operators and the surrounding environment from hazardous airborne particles. It uses reverse airflow to capture contaminants directly from the source, ensuring safety in operations involving potent compounds and powders.

Key Features & Benefits :

✅ Reverse Airflow Technology – Immediate contaminant capture.

✅ High-Efficiency Filtration – HEPA and pre-filter combination.

✅ Safe Powder Handling – Minimises the risk of cross-contamination.

✅ Robust Stainless Steel Design – Durable and GMP-compliant.

✅ Low Noise & Low Vibration – Enhances operator comfort.

Applications :

Weighing, dispensing, and sampling of active pharmaceutical ingredients, and hazardous powders.

Why Choose Our RLAF?

Engineered for operator safety, our RLAF meets both national and international containment standards, offering reliability, easy maintenance, and compliance for regulated industries.

The Bio Safety Cabinet ensures safe handling of pathogenic and biological agents by protecting the operator, product, and environment. Its advanced airflow system combines HEPA filtration with balanced inflow and downflow patterns to provide Class II biological safety.

Key Features & Benefits :

✅Triple Protection – Operator, product, and environment safety.

✅ HEPA Filter System – ISO Class 5 clean air quality.

✅ Negative Pressure Design – Prevents airborne escape.

✅ Ergonomic & Quiet – Designed for operator comfort.

✅Compliant with EN & NSF Standards – Global safety assurance.

Applications :

Microbiological research, cell culture, virology, and molecular biology labs.

Why Choose Our Bio Safety Cabinet?

Stringently tested for biosafety compliance, our cabinets deliver reliable performance for high-risk laboratory applications.

The Operating Field Containment System (OFCS) provides localized sterile environments for surgical and pharmaceutical applications. Its unidirectional airflow and HEPA filtration ensure contamination-free conditions right at the critical operation zone.

Key Features & Benefits :

✅ Localized Sterile Zone – Precision protection at the operating field.

✅ Advanced HEPA Filtration – ISO Class 5 air quality.

✅ Flexible Installation – Adapts to new or existing setups.

✅ High-Grade Stainless Steel – Hygienic and corrosion-resistant.

✅ Quiet Operation – Enhances workflow comfort.

Applications :

Surgical theaters, critical filling zones, compounding areas.

Why Choose Our OFCS?

Engineered for reliability, OFCS integrates advanced airflow control with easy maintenance and compliance to GMP standards, making it a trusted choice for high-precision operations.

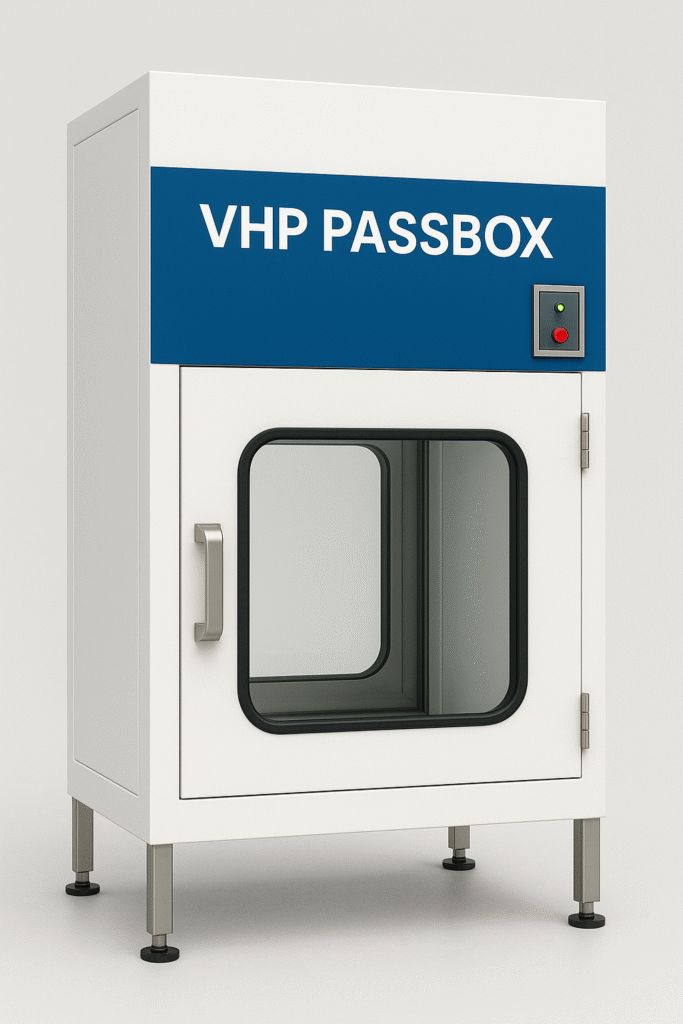

The VHP Passbox uses Vaporized Hydrogen Peroxide sterilization to decontaminate materials during transfer between controlled environments, ensuring zero microbial carryover.

Key Features & Benefits :

✅VHP Sterilization – Kills bacteria, viruses, and spores.

✅ HEPA Filtration – ISO Class 5 particle control.

✅ GMP-Compliant Stainless Steel – Easy to clean

✅ Automation Ready – Optional control integration.

✅Energy Efficient – Low operational cost.

Applications :

Pharma production, research labs, biosafety facilities.

Why Choose Our VHP Passbox?

Ensures secure, validated, and rapid material transfer without compromising cleanroom sterility.

The Dynamic Passbox maintains positive pressure with HEPA filtration during material transfer, preventing contamination ingress.

Key Features & Benefits :

✅ Airflow Purging – Continuous filtered air supply.

✅ HEPA Filtration – ISO Class 5 standards.

✅ Interlocking Doors – Prevents cross-contamination.

✅ Stainless Steel Build – Hygienic and durable.

✅ Easy Service Access – Simplified maintenance.

Applications :

Cleanrooms, R&D, food processing.

Why Choose Our Dynamic Passbox?

Delivers contamination-free material transfer while complying with stringent regulatory requirements. .

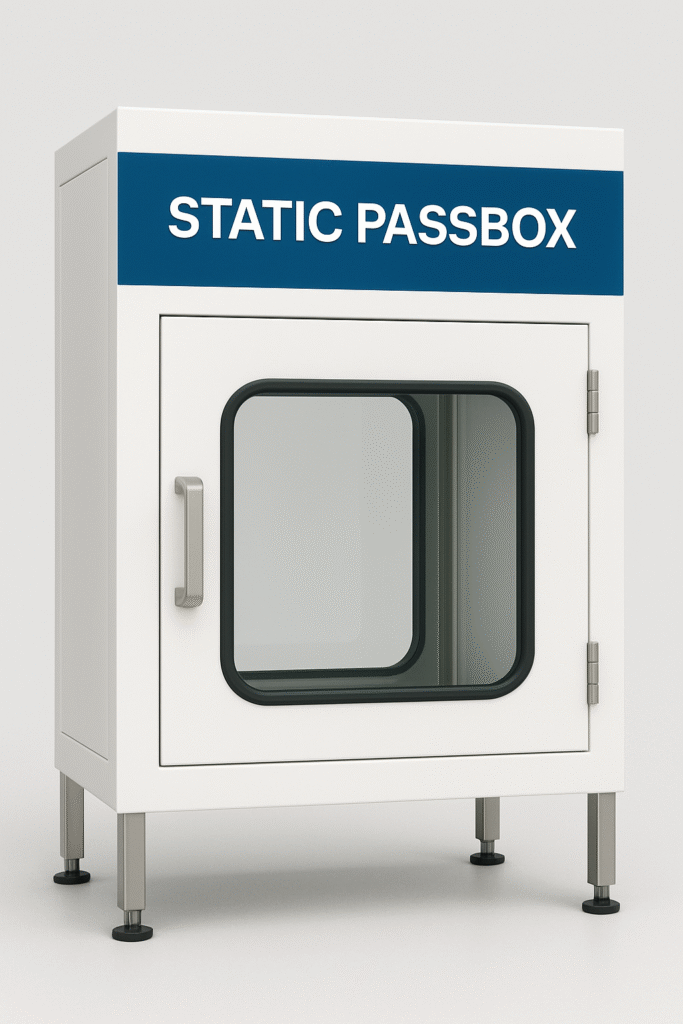

A cost-effective solution for transferring non-critical materials between controlled environments without active airflow.

Key Features & Benefits :

✅Mechanical Simplicity – No moving parts, minimal maintenance.

✅ Interlocked Doors – Prevents simultaneous opening.

✅ Stainless Steel Construction – Long-term durability.

✅ Compact Design – Space-saving.

✅Customizable Sizes – Fits various workflows.

Applications :

Laboratories, manufacturing plants, packaging areas.

Why Choose Our Static Passbox?

Reliable, low-maintenance solution for secure, contamination-controlled transfers.

Mist Air Passbox combines HEPA filtration with misting technology for added contamination control during transfers.

Key Features & Benefits :

✅ Fine Mist Spraying – Neutralizes particles and microbes.

✅ HEPA Filtration – Clean air delivery.

✅ GMP-Compliant Build – Hygienic surfaces.

✅ Interlocking System – Avoids contamination entry.

✅Customizable Options – Adjustable misting cycles.

Applications :

Pharmaceuticals, cleanroom packaging, R&D.

Why Choose Our Mist Air Passbox?

Extra protection for sensitive materials where sterility is paramount.

Air Showers use high-velocity HEPA-filtered air jets to remove particulates from personnel before entering cleanrooms.

Key Features & Benefits :

✅High-Velocity Air Jets – Efficient particle removal.

✅ HEPA Filtration – ISO Class 5 air.

✅Sensor-Activated Operation – Hands-free use

✅Corrosion-Resistant Build – Long life span.

✅Custom Size Options – Adaptable to site needs.

Applications :

Pharmaceutical, biotech, and semiconductor industries.

Why Choose Our Air Shower?

Ensures cleanroom integrity by preventing particulate entry from personnel.

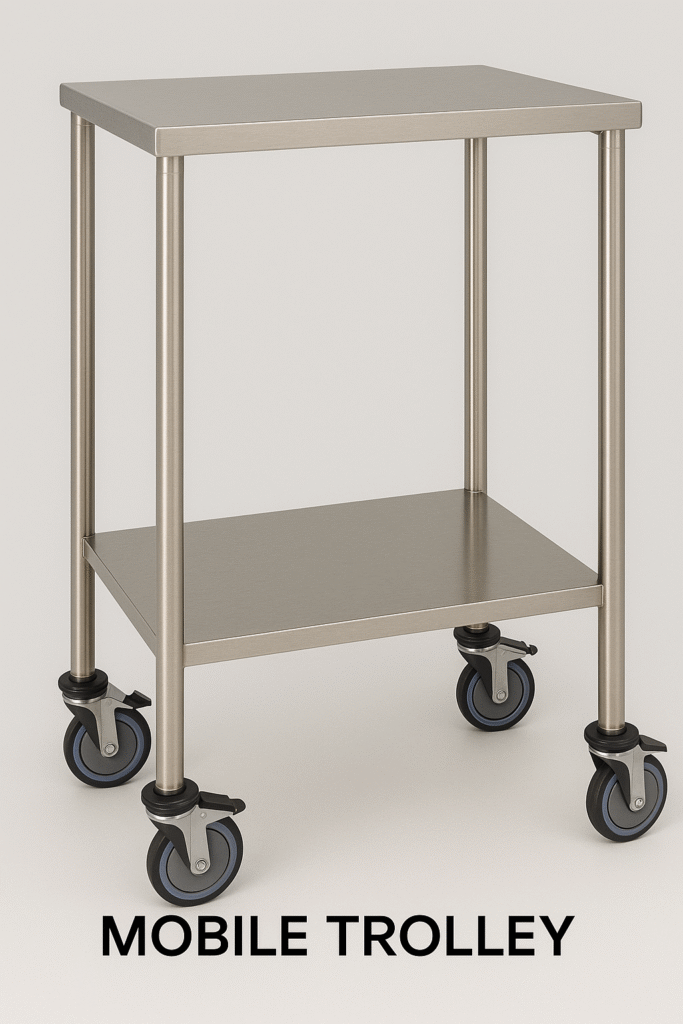

A contamination-controlled mobile platform designed for transporting sensitive materials in cleanroom facilities.

Key Features & Benefits :

✅Smooth Mobility – Low-vibration wheels.

✅Stainless Steel Build – Hygienic and durable.

✅ Compact & Lightweight – Easy handling.

✅ Custom Configurations – Tailored to material needs.

✅Easy Cleaning – Seamless welds for hygiene.

Applications :

Pharma manufacturing, biotech research, electronics.

Why Choose Our Mobile Trolley?

Reliable mobility solution that upholds cleanroom hygiene standards.

The ORAB provides partial physical barriers and controlled unidirectional airflow for open processing operations requiring sterility.

Key Features & Benefits :

✅Unidirectional Airflow – ISO Class 5 protection.

✅Ergonomic Design – Easy operator access.

✅ Stainless Steel Build – GMP-compliant surfaces.

✅ Low Energy Use – Efficient operation.

✅Custom Configurations – Tailored to process needs.

Applications :

Pharmaceutical filling lines, sterile compounding.

Why Choose Our ORAB?

Balances sterility assurance with operational flexibility.

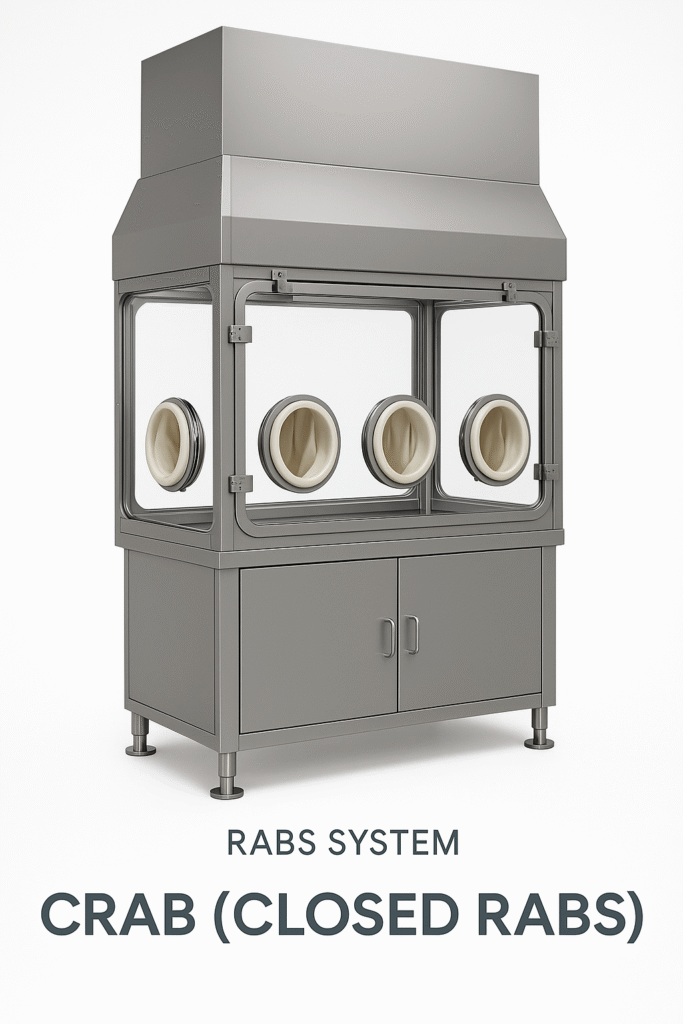

The CRAB offers full physical containment with unidirectional airflow for maximum product protection in sterile operations.

Key Features & Benefits :

✅Full Barrier Containment – Maximum sterility.

✅Glove Ports – Safe handling without exposure.

✅HEPA Filtration – ISO Class 5 air.

✅Positive or Negative Pressure Options – Process flexibility.

✅Easy Cleaning – Smooth, weld-free surfaces.

Applications :

High-potency drug manufacturing, aseptic filling.

Why Choose Our CRAB?

Delivers complete contamination control for critical processes.

The Air Cutter uses precision-directed airflow to prevent particulate ingress during sensitive manufacturing operations.

Key Features & Benefits :

✅Focused Air Stream – Blocks contaminants.

✅Low Noise – Operator comfort.

✅ Stainless Steel Build – Hygienic and durable.

✅Compact Form – Easy integration.

Applications :

Pharma packaging, electronics assembly.

Why Choose Our Air Cutter?

Reliable protection for micro-sensitive environments.

De-Dusty Booth removes airborne dust and particles during weighing, sampling, or dispensing operations.

Key Features & Benefits :

✅High Airflow Capture – Immediate dust removal.

✅HEPA Filtration – Clean exhaust air.

✅Ergonomic Design – Comfortable workspace.

✅Noise-Controlled – Operator-friendly.

✅Easy Maintenance – Accessible filter change.

Applications :

Powder handling in pharma and chemical industries.

Why Choose Our De-Dusty Booth?

Ensures cleaner, safer operations while meeting GMP standards.

Garment Cubicles keep cleanroom garments contamination-free before use through filtered airflow and controlled storage.

Key Features & Benefits :

✅Continuous HEPA Purge – Keeps garments particle-free.

✅Hygienic Storage – Stainless steel interior.

✅Compact Design – Space-efficient.

✅Low Energy Use – Cost-effective.

✅Customizable Size – Meets facility needs.

Applications :

Pharma plants, microelectronics, clean labs.

Why Choose Our Garment Cubicle?

Protects garments and ensures compliance with cleanroom protocols.

Compact spraying system for uniform application of disinfectants in controlled areas.

Key Features & Benefits :

✅Fine Mist Output – Even coverage.

✅Portable Design – Easy relocation.

✅Chemical Resistant Build – Long-lasting performance.

✅Low Noise – Operator-friendly.

✅Energy Efficient – Low operational cost.

Applications :

Pharma plants, laboratories, healthcare facilities.

Why Choose Our Micro Sprayer?

Delivers quick, effective, and uniform disinfection for sensitive spaces.