Negative Pressure Isolation

Built to safely handle HPAPI, OSD, and hazardous material with operator protection.

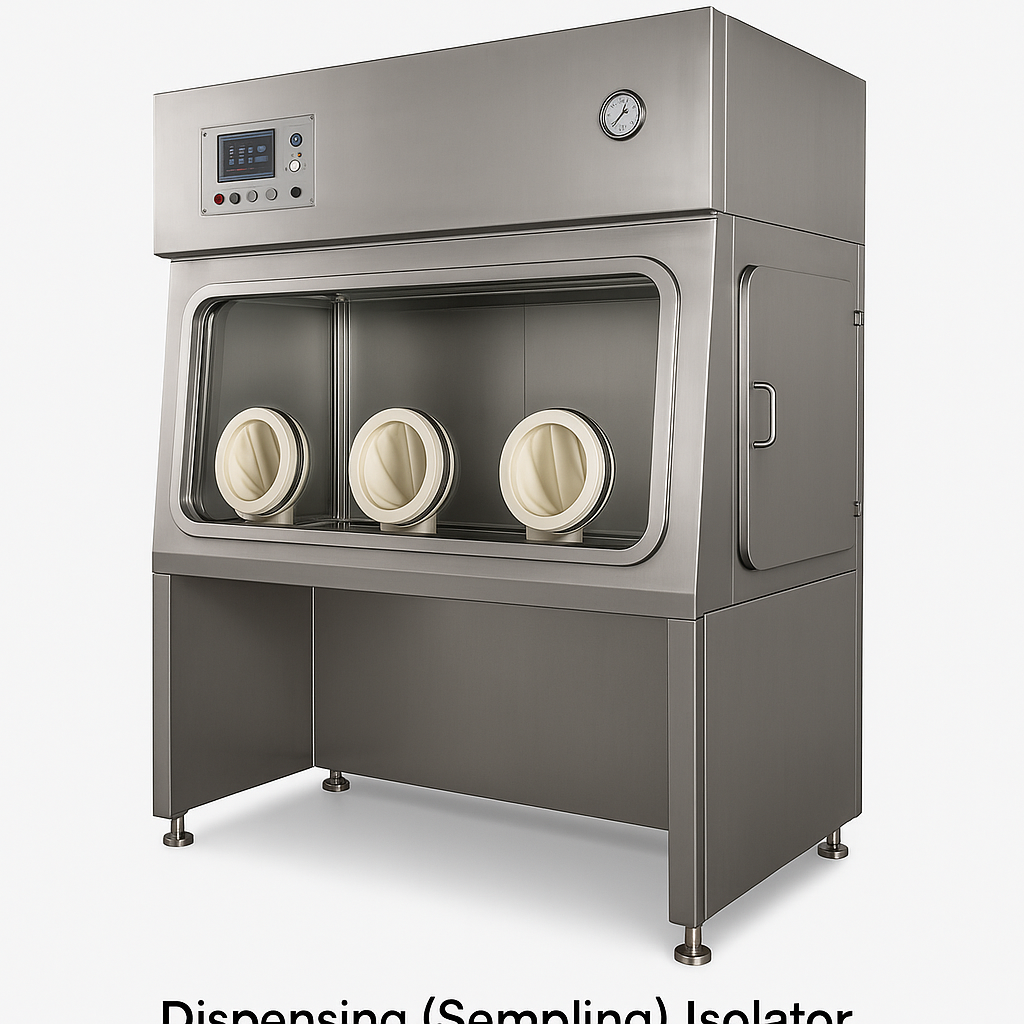

Engineered for safe and contamination-free dispensing of potent powders and hazardous materials, the Dispensing Isolator ensures both operator protection and product integrity. It operates under negative pressure with HEPA filtration for maximum containment.

Key Features & Benefits :

✅Operator & Product Safety – Negative pressure containment.

✅Dual HEPA Filtration – Meets international OEB levels.

✅Ergonomic Design – Comfortable glove port positioning.

✅ Easy Decontamination – Smooth interior surfaces.

✅Data Logging – GMP compliance ready.

Applications :

Pharma powder weighing, sampling, and transfer.

Designed for integrated containment during size reduction, blending, and final packing of APIs, this isolator minimizes airborne particle release and operator exposure.

Key Features & Benefits :

✅Integrated Multi-Process Design – Milling, blending, and packing.

✅Negative Pressure Safety – Protects personnel.

✅ Dust-Free Operation – Prevents cross-contamination.

✅Robust Stainless Steel Build – Longevity and hygiene.

✅Flexible Equipment Integration – Modular.

Applications :

API processing and final containment packaging.

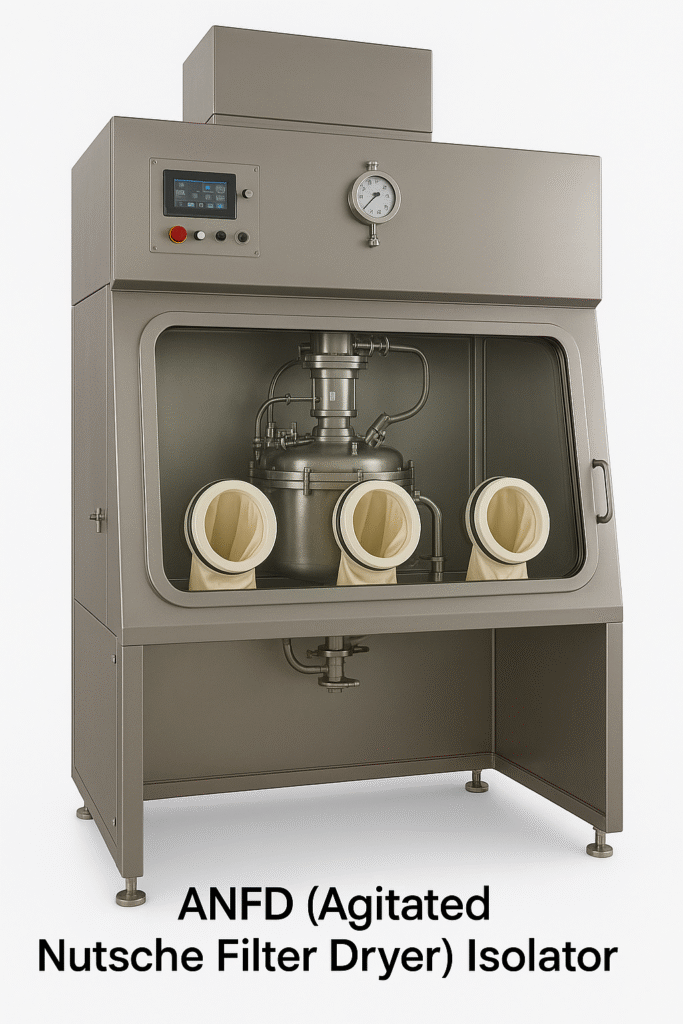

This isolator ensures safe filtration, drying, and product discharge from ANFD systems under controlled containment.

Key Features & Benefits :

✅Seamless ANFD Integration – Optimized workflow.

✅OEL Compliance – For potent compounds.

✅Efficient Cleaning Access – CIP/SIP ready.

✅ Pressure Control – Consistent negative pressure.

✅Durable Build – GMP-grade materials.

Applications :

API filtration and drying operations.

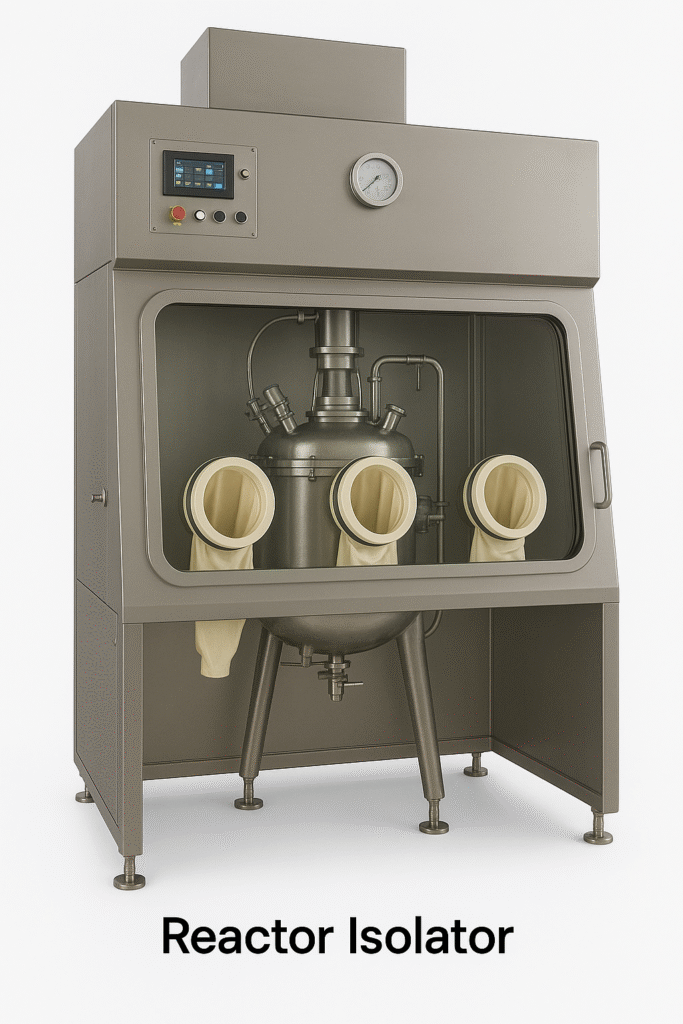

The Reactor Isolator allows safe handling of toxic or potent materials during reactor charging, sampling, or maintenance.

Key Features & Benefits :

✅Full Reactor Access – Contained environment.

✅High-Level Containment – Negative pressure + HEPA.

✅Flexible Port Configuration – Adaptable to process.

✅Easy Decon & Cleaning – Smooth finishes.

✅Compliant with cGMP – Quality assured.

Applications :

Chemical and pharmaceutical reactor operations.

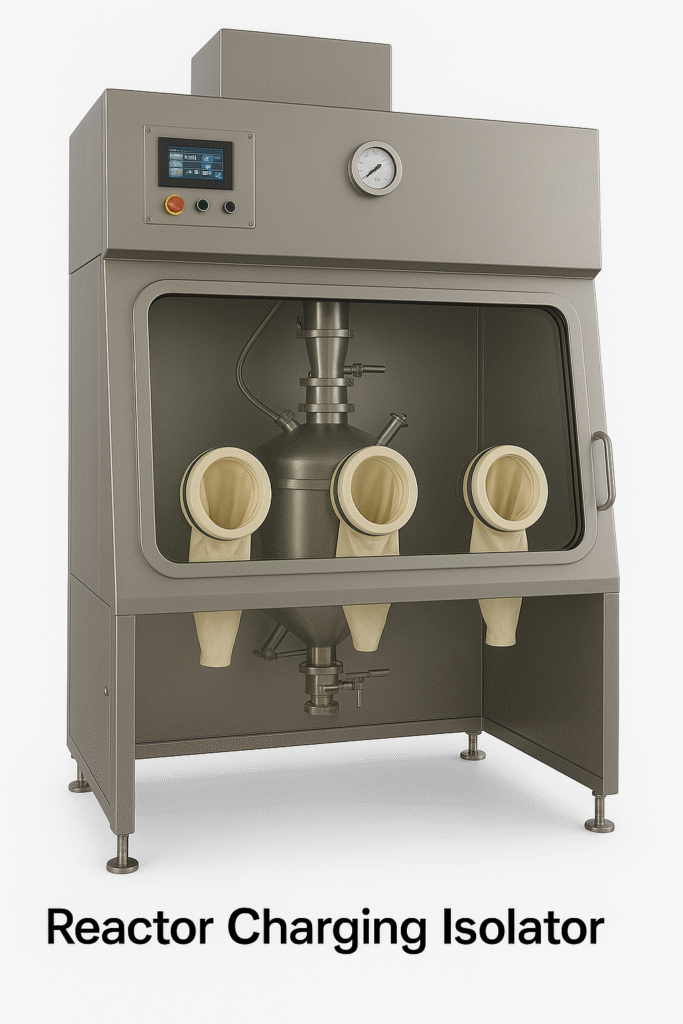

Provides secure and dust-free addition of powders or liquids into reactors while protecting operators from hazardous exposure.

Key Features & Benefits :

✅Contained Charging – No dust escape.

✅Negative Pressure Control – Safety assured.

✅Ergonomic Access – Reduces operator strain.

✅HEPA Filtration – Particle control.

✅Quick Cleaning – Easy turnaround.

Applications :

Safe material charging in pharmaceutical and chemical reactors.

A sealed workspace for the handling of toxic or sensitive materials, the glove box ensures safe manipulation under negative pressure containment.

Key Features & Benefits :

✅High-Level Containment – Safe handling of potent compounds.

✅Customizable Layout – Process-specific design.

✅Clear Viewing Panels – Maximum visibility.

✅HEPA Filtration – Particle removal.

✅Durable & Hygienic – Stainless steel interior.

Applications :

Research, testing, and small-scale containment tasks.

Designed to fully enclose the VTD process, this isolator ensures containment of potent materials during drying and unloading.

Key Features & Benefits :

✅Complete VTD Integration – Optimized space use.

✅OEL Compliance – High containment performance.

✅Easy Loading & Unloading – Ergonomic design.

✅Cleanable Surfaces – GMP-ready finish.

✅Controlled Airflow – Negative pressure safety.

Applications :

Drying potent APIs and hazardous powders.

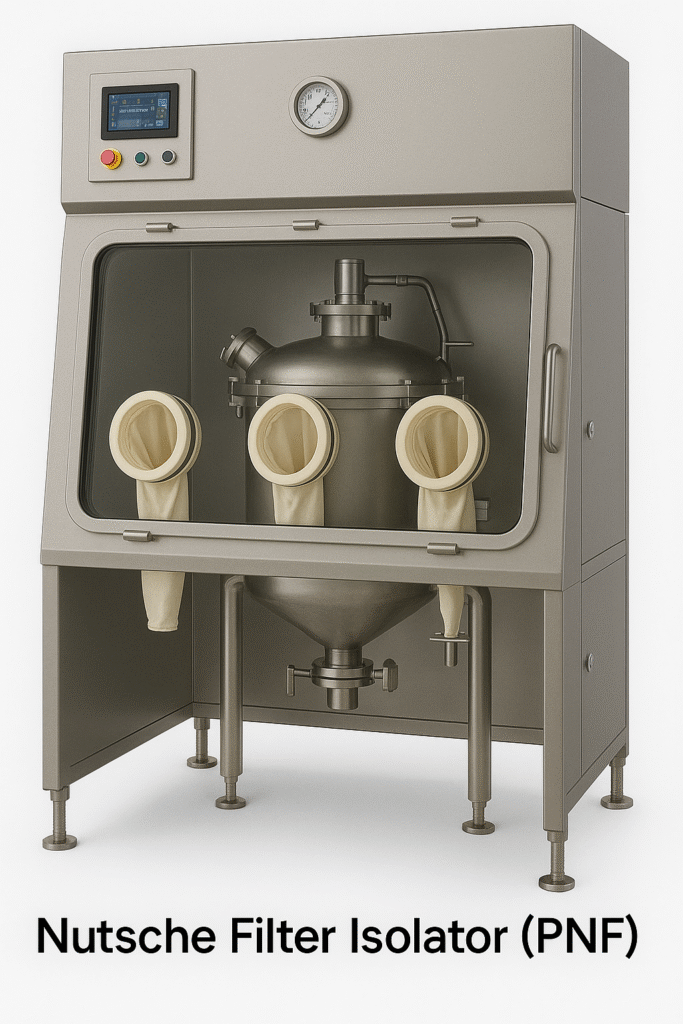

Provides full containment for filtration and cake handling processes, protecting both operators and product purity.

Key Features & Benefits :

✅Integrated PNF Operation – Seamless workflow.

✅Negative Pressure Control – Operator safety.

✅CIP/SIP Compatibility – Efficient cleaning.

✅Durable Stainless Steel – Long service life.

✅Customizable Configuration – Fits process needs.

Applications :

Pharmaceutical filtration and handling of potent products.

Ensures dust-free packing of finished APIs or hazardous powders into containers, with operator protection as a priority.

Key Features & Benefits :

✅Contained Packing Process – Prevents dust release.

✅Negative Pressure Safety – OEL-compliant.

✅Easy Cleaning Access – Quick turnaround.

✅Ergonomic Design – Comfortable operation.

✅Robust Build – GMP-grade.

Applications :

Packing of APIs and high-potency products.

Provides safe transfer and sampling of bulk powders from drums into the process line with full containment.

Key Features & Benefits :

✅ Contained Drum Handling – Dust-free operation.

✅Dual HEPA Filtration – Maximum particle control.

✅Flexible Loading Ports – Process adaptability.

✅Negative Pressure Design – Safety assured.

✅Easy Cleaning – Smooth surfaces.

Applications :

Pharma and chemical bulk powder loading.

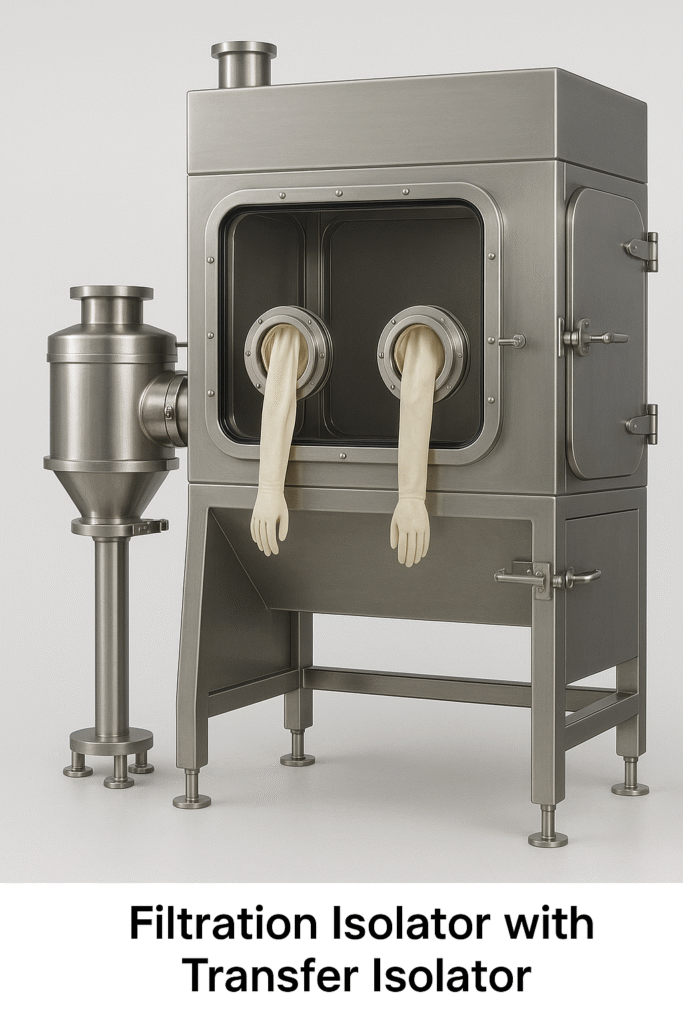

Designed for safe and contained filtration of potent materials, ensuring purity and operator safety.

Key Features & Benefits :

✅Integrated Filtration System – Seamless workflow.

✅OEL-Compliant Containment – Protects operators.

✅HEPA Filtration – Particle-free exhaust.

✅Easy Cleaning – Smooth, GMP-grade finish.

✅Customizable Ports – Flexible use.

Applications :

Pharma and biotech filtration processes.

Ensures contained powder handling during sifting or sieving operations, preventing dust exposure and product loss.

Key Features & Benefits :

✅ Integrated Sieving Equipment – High efficiency.

✅Negative Pressure Safety – Operator protection.

✅Dust-Free Operation – Preserves cleanroom integrity.

✅Easy Cleaning & Maintenance – GMP-compliant design.

✅Durable Build – Long operational life.

Applications :

Powder classification in pharma and chemical production.