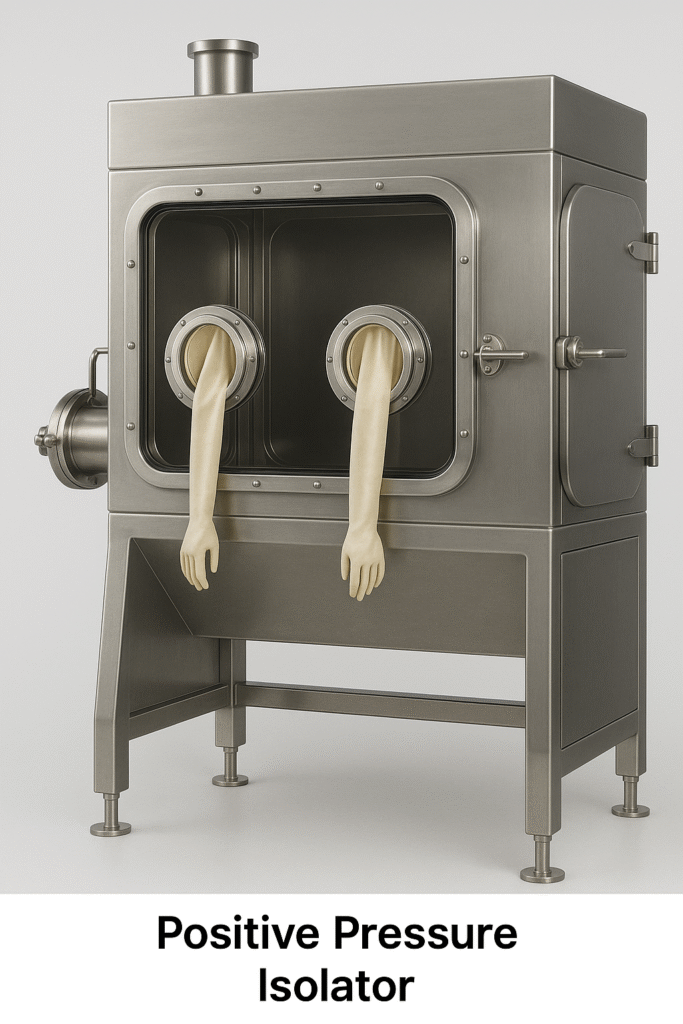

Positive Pressure Isolators

Key Features & Benefits :

✅Controlled Positive Pressure Environment – Ensures sterility by preventing airborne contaminants from entering.

✅Advanced HEPA/ULPA Filtration – Achieves ISO Class 5 or better cleanliness standards.

✅ Seamless Stainless-Steel Build – Durable, corrosion-resistant, and compliant with GMP.

✅Ergonomic Glove Ports – Enables safe and precise handling of sensitive materials.

✅Integrated Monitoring Systems – Real-time display of pressure, airflow, and particle count.

✅LED-Illuminated Workspace – Enhances visibility while reducing operator fatigue.

Applications :

Perfect for aseptic compounding, sterile product filling, batch sampling, and high-purity packaging in pharmaceutical, biotech, and healthcare facilities.

Why Choose Our Positive Pressure Isolator?

Our Positive Pressure Isolator combines cutting-edge airflow engineering with user-friendly design to deliver unmatched protection for sensitive operations. The system’s real-time environmental monitoring and easy-to-clean surfaces simplify compliance with stringent GMP and regulatory requirements. Every unit undergoes comprehensive factory acceptance testing (FAT) and can be customised for integration into existing cleanroom setups.