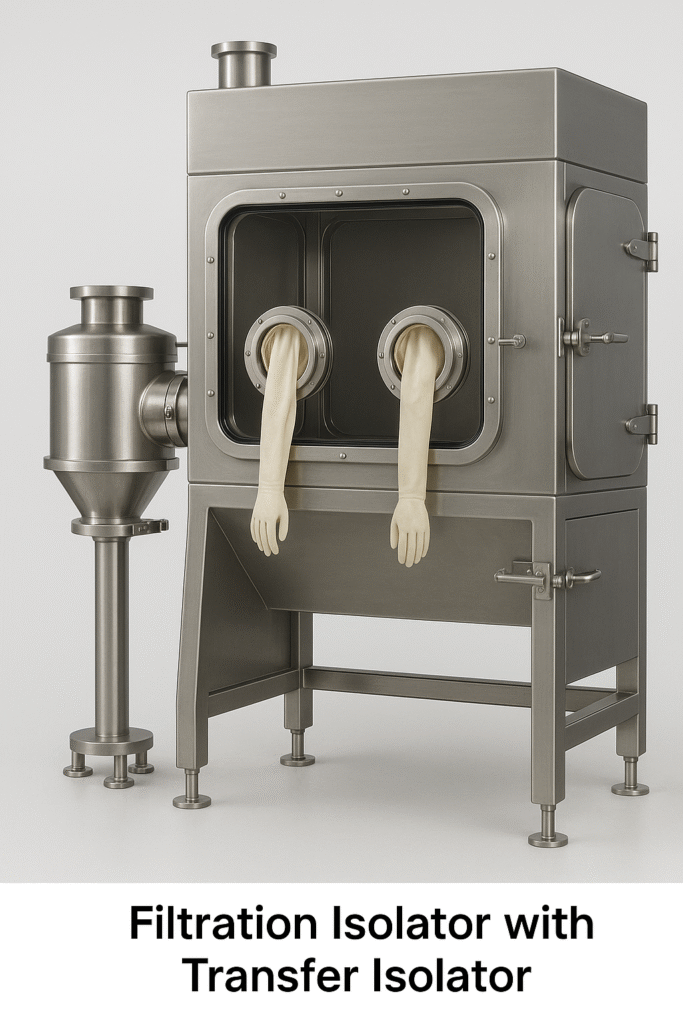

Positive Pressure Isolators

Maintain product sterility during fill-finish and critical batch processing.

Key Features & Benefits :

✅Dual-Chamber Design – Integrates filtration and transfer in one compact footprint.

✅Positive Pressure Protection – Maintains sterile conditions by preventing ingress of unfiltered air.

✅High-Efficiency HEPA/ULPA Filtration – Delivers ISO Class 5 or better air quality.

✅ Ergonomic Glove Ports – Provides safe, comfortable handling of materials.

✅Integrated Decontamination System – Ensures quick turnaround between batches.

✅Robust Stainless-Steel Construction – Easy to clean, corrosion-resistant, and GMP-compliant.

Applications :

Ideal for aseptic filtration, sterile bulk product transfer, and integration with filling or packaging lines in pharmaceutical, biotech, and high-purity manufacturing environments.

Why Choose Our Filtration Isolator with Transfer Isolator?

Our system combines precise airflow management with user-focused ergonomics to enhance both product safety and operator efficiency. With its integrated filtration and secure transfer capabilities, it reduces handling steps, minimizes risk, and accelerates workflow. Each unit is rigorously tested and validated to meet the strictest contamination control requirements.

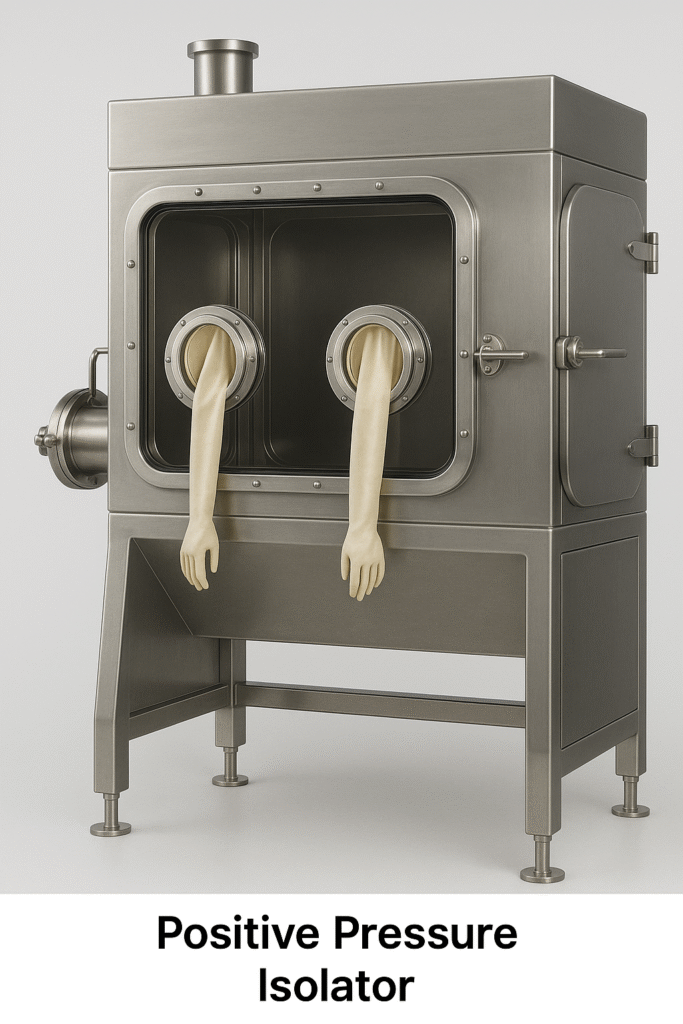

Key Features & Benefits :

✅Controlled Positive Pressure Environment – Ensures sterility by preventing airborne contaminants from entering.

✅Advanced HEPA/ULPA Filtration – Achieves ISO Class 5 or better cleanliness standards.

✅ Seamless Stainless-Steel Build – Durable, corrosion-resistant, and compliant with GMP.

✅Ergonomic Glove Ports – Enables safe and precise handling of sensitive materials.

✅Integrated Monitoring Systems – Real-time display of pressure, airflow, and particle count.

✅LED-Illuminated Workspace – Enhances visibility while reducing operator fatigue.

Applications :

Perfect for aseptic compounding, sterile product filling, batch sampling, and high-purity packaging in pharmaceutical, biotech, and healthcare facilities.

Why Choose Our Positive Pressure Isolator?

Our Positive Pressure Isolator combines cutting-edge airflow engineering with user-friendly design to deliver unmatched protection for sensitive operations. The system’s real-time environmental monitoring and easy-to-clean surfaces simplify compliance with stringent GMP and regulatory requirements. Every unit undergoes comprehensive factory acceptance testing (FAT) and can be customised for integration into existing cleanroom setups.